The Complexities Of Automated Nike Sneaker Manufacturing

Table of Contents

Technological Hurdles in Automated Sneaker Production

Automating Nike's sneaker production faces significant technological hurdles. The complex manufacturing process, involving diverse materials and intricate steps, requires advanced robotics and sophisticated software solutions.

Robotics and Dexterity

The intricate nature of shoe assembly demands a high degree of dexterity and precision that current robotics struggle to replicate consistently.

- Complex stitching patterns: Many Nike shoe designs utilize complex stitching patterns that require fine motor skills beyond the capabilities of current robotic arms.

- Delicate material handling: Working with delicate materials like leather, suede, and mesh requires careful handling to avoid damage, a challenge for robotic grippers.

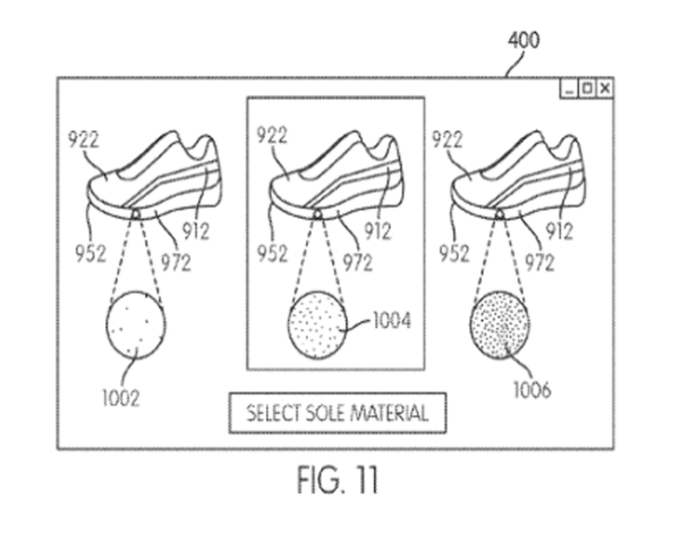

- Variable shoe sizes and designs: Nike produces a vast array of shoe sizes and designs, requiring flexible automation that can adapt to these variations.

Current robotic arms and grippers lack the adaptability and precision needed for consistent, high-quality assembly. Tasks such as accurately placing eyelets, threading laces, and applying adhesives with precision remain significant challenges. Further advancements in robotic dexterity and sensor technology are crucial for overcoming these limitations.

Material Handling and Supply Chain Integration

Integrating automated systems with existing supply chains and material handling processes presents another major hurdle. This requires substantial investment and careful planning.

- Precise material feeding systems: Automated systems need consistent and reliable material feeding to function effectively. This requires sophisticated systems to manage and track the flow of materials.

- Automated quality control checkpoints: Automated quality control checkpoints are vital to ensure the high standards of Nike products. This requires advanced vision systems and sensor technology.

- Real-time inventory management: Efficient real-time inventory management is critical to optimize production flow and minimize downtime.

The logistical challenge of moving components efficiently through an automated production line is considerable. Implementing precise sensors and tracking systems throughout the entire process is essential for monitoring material flow, identifying bottlenecks, and ensuring seamless integration with existing infrastructure.

Software and Programming Complexity

Programming and maintaining sophisticated robotic systems requires specialized expertise and significant upfront investment.

- Software development: Developing the software to control and coordinate the various robotic systems and processes is a complex undertaking.

- System integration: Seamless integration of various automated systems is crucial for efficient operation, presenting significant software engineering challenges.

- Ongoing maintenance and updates: Maintaining and updating the complex software and robotic systems requires ongoing investment and specialized skills.

Developing adaptable software that can handle variations in shoe designs and manufacturing processes is a key challenge. The software must be flexible enough to accommodate new designs and production methods while ensuring consistent quality and efficiency.

Economic Considerations of Automation in Nike Sneaker Manufacturing

While the potential benefits of automated Nike sneaker manufacturing are substantial, significant economic considerations must be addressed.

High Initial Investment Costs

The upfront costs associated with implementing automated systems are substantial.

- Robotics purchase: The cost of purchasing advanced industrial robots capable of performing intricate tasks is significant.

- Software development: Developing and implementing the necessary software represents a considerable investment.

- Facility modifications: Existing facilities often require significant modifications to accommodate automated systems.

- Employee retraining: Retraining employees to work alongside robots and maintain automated systems is essential.

Estimates for the capital investment required to automate a significant portion of Nike's production run into the hundreds of millions of dollars, representing a substantial financial commitment.

Return on Investment (ROI) and Break-Even Point

Determining the ROI of automation requires careful analysis of cost savings versus investment costs.

- Reduced labor costs: Automation can lead to significant reductions in labor costs.

- Increased production efficiency: Automated systems can often increase production efficiency and output.

- Potential for higher quality control: Automated quality control can lead to fewer defects and higher quality products.

The ROI depends on factors such as production volume, defect rates, and labor costs in different regions. A thorough cost-benefit analysis is crucial to determine the feasibility and profitability of automation initiatives.

Job Displacement and Workforce Transition

Automation can lead to job displacement, necessitating strategic workforce planning and retraining initiatives.

- Reskilling programs: Nike has a responsibility to provide reskilling programs for employees affected by automation.

- Alternative employment opportunities: The company should explore opportunities for displaced workers within the organization or through partnerships.

- Addressing ethical concerns: Addressing the ethical concerns of job displacement is paramount.

Nike must adopt responsible strategies to mitigate the negative impacts of automation on its workforce, fostering a just transition for its employees.

The Future of Automated Nike Sneaker Manufacturing

Despite current challenges, advancements in technology offer promising solutions for the future of automated Nike sneaker manufacturing.

Emerging Technologies and Advancements

Advances in AI, machine learning, and robotics offer potential solutions to current challenges.

- Improved dexterity in robotics: Advancements in robotics are continuously improving dexterity and precision, addressing a major hurdle in automated shoe assembly.

- AI-powered quality control: AI-powered systems can enhance quality control by detecting defects more efficiently and accurately.

- Predictive maintenance systems: Predictive maintenance systems can minimize downtime by anticipating and preventing equipment failures.

These technologies hold the key to overcoming many of the current limitations of automated sneaker production, paving the way for more efficient and effective processes.

Sustainability and Ethical Considerations

Automated systems can potentially reduce waste and improve sustainability.

- Reduced material waste: Precise and efficient automated systems can minimize material waste.

- Optimized energy consumption: Automation can lead to optimized energy consumption in the manufacturing process.

- Environmentally friendly manufacturing processes: Automation can facilitate the implementation of more environmentally friendly manufacturing processes.

By adopting sustainable automation practices, Nike can reduce its environmental footprint and demonstrate a commitment to corporate social responsibility.

The Role of Human Workers in Automated Factories

The future likely involves a collaboration between humans and robots, leveraging the strengths of both.

- Human oversight: Human oversight will remain crucial for monitoring and controlling complex automated systems.

- Complex problem-solving: Human workers are essential for solving complex problems and adapting to unexpected situations.

- Specialized tasks requiring dexterity: Tasks requiring fine motor skills and adaptability will continue to be performed by humans.

The most effective approach will involve integrating human expertise with automated systems, creating a collaborative environment where human workers focus on high-value tasks requiring judgment and adaptability while robots handle repetitive and precise operations.

Conclusion

Automated Nike sneaker manufacturing presents significant challenges and opportunities. While technological hurdles and economic considerations remain, advancements in AI and robotics hold the key to overcoming these obstacles. The future likely involves a collaborative model combining human expertise with sophisticated automation. Nike's journey toward fully automated production will require careful planning, significant investment, and a commitment to ethical and sustainable practices. Understanding the complexities of automated Nike sneaker manufacturing is crucial for navigating the future of footwear production. To stay informed on the latest developments in this rapidly evolving field, continue to research the advancements in automated Nike sneaker manufacturing, exploring the potential for increased efficiency, sustainability, and ethical production in the industry.

Featured Posts

-

Improving Security Relations China And Indonesias Strategic Dialogue

Apr 22, 2025

Improving Security Relations China And Indonesias Strategic Dialogue

Apr 22, 2025 -

Chat Gpts Creator Open Ai Under Federal Trade Commission Investigation

Apr 22, 2025

Chat Gpts Creator Open Ai Under Federal Trade Commission Investigation

Apr 22, 2025 -

Turning Trash To Treasure An Ai Powered Podcast From Scatological Documents

Apr 22, 2025

Turning Trash To Treasure An Ai Powered Podcast From Scatological Documents

Apr 22, 2025 -

Office365 Data Breach Leads To Multi Million Dollar Theft

Apr 22, 2025

Office365 Data Breach Leads To Multi Million Dollar Theft

Apr 22, 2025 -

Hegseths Signal Chat Controversy Pentagon Disarray Allegations Surface

Apr 22, 2025

Hegseths Signal Chat Controversy Pentagon Disarray Allegations Surface

Apr 22, 2025