Automation In The Sneaker Industry: The Case Of Nike

Table of Contents

Automated Manufacturing Processes at Nike

Nike's commitment to efficiency and innovation is evident in its widespread adoption of automated manufacturing processes. This commitment translates into significant improvements in production speed, quality, and cost-effectiveness.

Robotics in Sneaker Production

Robotic automation plays a pivotal role in Nike's factories. Sophisticated robots perform intricate tasks previously handled by human workers, significantly boosting productivity. These robots, often found in factories across Asia and potentially increasingly in automated facilities closer to Nike's headquarters, are utilized for:

- Precise stitching: Robots ensure consistent stitch quality and speed, minimizing errors.

- Automated assembly: Robots handle the complex process of assembling various sneaker components with unparalleled accuracy.

- Rigorous quality control: Robotic vision systems inspect finished products, identifying defects far more efficiently than human inspectors.

This robotic automation in Nike's manufacturing streamlines production, reduces production time, and enhances the overall quality of its products. The use of advanced robotic arms and collaborative robots (cobots) are leading examples of Nike's investment in automated manufacturing.

3D Printing and its Impact

Nike's exploration of 3D printing, also known as additive manufacturing, represents a revolutionary step in footwear production. This technology allows for:

- Rapid prototyping: Designers can quickly create and test various sneaker designs, accelerating the development process.

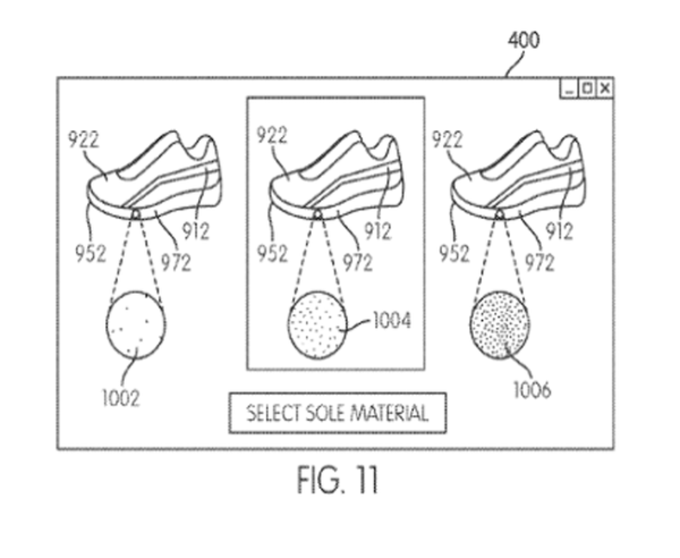

- Customized footwear: 3D printing enables the creation of personalized sneakers tailored to individual customer specifications, opening exciting avenues for bespoke footwear.

- Reduced material waste: 3D printing uses materials only where needed, minimizing waste compared to traditional manufacturing methods.

While scaling 3D printing for mass production presents challenges, its potential to revolutionize the sneaker industry and Nike's production capabilities is undeniable. "3D printed sneakers" are becoming increasingly feasible and are a key component of Nike's innovation strategy.

AI-powered Supply Chain Optimization

Nike leverages AI to optimize its global supply chain, leading to:

- Enhanced forecasting accuracy: AI algorithms analyze vast datasets to predict demand more precisely, reducing inventory holding costs and preventing stockouts.

- Automated logistics: AI optimizes transportation routes and warehouse management, improving delivery speed and efficiency.

- Minimized disruptions: AI systems can identify and address potential supply chain disruptions proactively, mitigating risks and ensuring production continuity.

The integration of AI in Nike's supply chain is a prime example of how automation enhances efficiency and resilience across the entire production process. This "Nike supply chain automation" strategy improves responsiveness to market demands.

Automation in Nike's Design and Development

Automation isn't limited to manufacturing; it significantly impacts Nike's design and development processes.

Digital Design Tools and Software

Nike utilizes advanced Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software to streamline its design workflows:

- Faster iterations: Designers can quickly create and modify designs digitally, accelerating the design process and allowing for more experimentation.

- Improved collaboration: Digital platforms facilitate seamless collaboration between designers, engineers, and manufacturers across geographical locations.

- Digital prototyping: Virtual prototypes allow for early testing and refinement of designs before physical production, reducing costs and development time.

The transition to digital design tools has fundamentally altered Nike's design process, boosting efficiency and creativity. The impact of "CAD/CAM in footwear" is undeniable in the speed and sophistication of modern sneaker designs.

Data Analytics for Consumer Insights

Nike leverages data analytics and AI to gain profound consumer insights:

- Targeted market research: Analyzing consumer data helps identify trends, preferences, and unmet needs, informing product development.

- Personalized marketing campaigns: Data-driven insights enable Nike to create highly targeted marketing campaigns, enhancing engagement and sales.

- Improved product development: By understanding consumer feedback and preferences, Nike can develop products that better meet market demands.

This "data-driven design" approach allows Nike to anticipate market trends and create products that resonate with its target audience, boosting brand loyalty and sales. "Nike market research automation" plays a critical role in driving this success.

The Future of Automation in Nike's Operations

The future of automation in Nike's operations promises even greater advancements.

Emerging Technologies

Future trends shaping Nike's automation strategy include:

- AI-powered personalization: Further development of AI algorithms will enable Nike to create even more highly customized footwear and apparel.

- Advanced robotics: The use of more sophisticated robots will likely automate even more complex tasks in the manufacturing process.

- Sustainable automation practices: Focus will shift towards environmentally friendly automation technologies, reducing the industry's environmental impact.

These advancements will redefine "the future of automation" within Nike and across the wider sneaker industry.

Challenges and Opportunities

While automation presents significant opportunities, challenges remain:

- High initial investment costs: Implementing advanced automation technologies requires significant upfront investment.

- Workforce transition: Automation may lead to job displacement, requiring strategic workforce retraining and reskilling initiatives.

- Ethical considerations: The ethical implications of widespread automation in manufacturing need careful consideration.

Despite these challenges, the long-term benefits of automation for Nike—increased efficiency, improved product quality, greater sustainability—far outweigh the initial hurdles. Addressing these "challenges of automation" head-on will pave the way for realizing the enormous "opportunities of automation" available.

Conclusion: The Impact of Automation on Nike's Success

Automation is profoundly impacting Nike's manufacturing, design, and marketing operations. From robotic assembly lines to AI-powered supply chain optimization, automation enhances efficiency, reduces costs, and allows for greater innovation and personalization. This integration of technology is crucial to Nike's continued success and its ability to maintain a competitive edge in the rapidly evolving sneaker industry.

Explore the advancements in automation in the footwear industry and learn more about Nike's innovative use of automation to discover the future of automated sneaker production. The strategic integration of automation technologies is shaping not only Nike's future but the entire sneaker industry's trajectory.

Featured Posts

-

Post Roe America How Over The Counter Birth Control Changes The Game

Apr 22, 2025

Post Roe America How Over The Counter Birth Control Changes The Game

Apr 22, 2025 -

Bmw Porsche And The Complexities Of The Chinese Automotive Market

Apr 22, 2025

Bmw Porsche And The Complexities Of The Chinese Automotive Market

Apr 22, 2025 -

The Complexities Of Automated Nike Sneaker Manufacturing

Apr 22, 2025

The Complexities Of Automated Nike Sneaker Manufacturing

Apr 22, 2025 -

Stock Market Valuations Bof A Explains Why Investors Shouldnt Worry

Apr 22, 2025

Stock Market Valuations Bof A Explains Why Investors Shouldnt Worry

Apr 22, 2025 -

Dojs Renewed Legal Challenge Against Googles Search Monopoly

Apr 22, 2025

Dojs Renewed Legal Challenge Against Googles Search Monopoly

Apr 22, 2025