Robotics In Footwear: The Hurdles To Automated Nike Production

Table of Contents

The Complexity of Footwear Manufacturing

Footwear manufacturing is inherently complex, presenting unique challenges for robotic automation. The intricate assembly process requires a level of dexterity and precision currently beyond the capabilities of most robots.

Dexterous Manipulation

Many steps in shoe production demand fine motor skills. Robots struggle to replicate the human hand's agility.

- Lacing: The precise threading of laces through eyelets remains a challenge for robotic systems.

- Stitching intricate designs: Creating complex stitching patterns with varying tension and thread types requires sophisticated control and adaptability.

- Attaching delicate components: Securely affixing small, fragile parts like decorative elements or insoles necessitates high precision and gentle handling.

Current robotic grippers often lack the sensitivity and adaptability needed for these tasks. They require more advanced sensory feedback and improved dexterity to handle the nuances of footwear materials and assembly. The development of more sophisticated grippers, mimicking the dexterity of the human hand, is crucial for progress in this area.

Material Variety and Handling

The diverse range of materials used in footwear production – leather, synthetics, textiles, and rubber – presents further challenges. Each material possesses unique properties affecting how it can be handled by robotic systems.

- Material flexibility: Adapting to the varying flexibility of different materials is critical.

- Material texture: Gripping and manipulating materials with different textures (smooth leather vs. rough canvas) requires adaptable gripper designs.

- Potential for damage: Avoiding damage to delicate materials during automated handling is paramount.

This necessitates the development of adaptive robotics and advanced material recognition systems. Robots need to "understand" the properties of each material to handle it appropriately, minimizing the risk of damage or defects.

Cost and Return on Investment (ROI)

Implementing advanced robotic systems in footwear manufacturing requires a substantial upfront investment, raising concerns about the overall return on investment.

High Initial Investment

The cost of integrating robotics into existing production lines is significant.

- Robotic arms: High-precision robotic arms capable of performing intricate tasks are expensive.

- Sensors and software: Advanced sensors and sophisticated control software are essential components adding to the cost.

- Integration and skilled technicians: Integrating robotic systems into existing production lines requires specialized expertise and significant labor costs.

A detailed cost-benefit analysis is crucial before implementing automation. Companies must carefully weigh the potential increase in production efficiency against the significant initial investment and ongoing maintenance expenses.

Maintenance and Downtime

Complex robotic systems are prone to malfunctions and require regular maintenance.

- Repair costs: Repairing sophisticated robotic components can be expensive and time-consuming.

- Programming issues: Software glitches or programming errors can lead to production downtime.

- Unexpected failures: Malfunctions can cause significant delays, disrupting production schedules.

Investing in robust and reliable robotic systems that minimize downtime is crucial for a positive ROI. Regular maintenance and preventative measures are essential to reduce the risk of costly disruptions.

Lack of Adaptability and Scalability

The ability to adapt to changing demands and scale production efficiently is crucial for footwear manufacturers. Current robotic systems often lack the necessary flexibility.

Customization and Personalization

The increasing trend towards customized and personalized footwear poses a significant challenge for automation.

- Varying design specifications: Adapting robotic systems to handle unique design specifications for each customer order is difficult.

- Individual customer requests: Meeting specific customer requirements for size, material, and design features adds complexity to automation.

This calls for more flexible and reconfigurable robotic systems capable of handling a wide range of customized orders without extensive reprogramming.

Production Line Integration

Integrating robotic systems into existing production lines is a complex undertaking.

- Compatibility issues: Ensuring seamless compatibility between robotic systems and existing equipment can be challenging.

- Workflow adjustments: Integrating robots often necessitates adjustments to existing workflows and production processes.

- Seamless integration with human workers: Achieving smooth collaboration between robots and human workers requires careful planning and implementation.

In many cases, this may require a complete re-engineering of existing production lines, adding to the overall cost and complexity of implementation.

The Human Factor

The introduction of robotics into footwear manufacturing raises important considerations regarding the workforce.

Job Displacement Concerns

Automation has the potential to displace factory workers, requiring proactive measures to mitigate its impact.

- Impact on factory workers: Job losses due to automation can have significant social and economic consequences.

- Retraining and upskilling initiatives: Investing in retraining and upskilling programs is crucial to help displaced workers transition to new roles.

Addressing these concerns through responsible implementation and investment in worker retraining is crucial for a just transition.

Quality Control and Human Oversight

Despite advancements in robotics, human oversight remains essential for quality control and certain aspects of footwear production.

- Subjective judgment: Some tasks, such as evaluating the aesthetic quality of finished products, require human judgment.

- Intricate handwork: Certain intricate tasks may require the dexterity and finesse of skilled human workers.

- Problem-solving capabilities: Humans are better equipped than robots to solve unexpected problems or handle unforeseen circumstances on the production line.

A collaborative approach, combining the strengths of robots and humans, is likely to be the most effective strategy for optimizing footwear production.

Conclusion

The journey towards fully automated footwear production presents significant challenges. The complexity of footwear manufacturing, high costs and ROI concerns, the lack of adaptability and scalability in current robotic systems, and the important human factor all contribute to the hurdles facing Nike and other footwear manufacturers. While complete automation remains a distant goal, ongoing advancements in robotics and AI offer a promising future outlook. Continued research, development, and a collaborative approach between engineers, manufacturers, and policymakers are vital to overcome these obstacles. Explore related articles and resources to stay informed about advancements in "Robotics in Footwear" and contribute to the discussion on achieving a more automated and efficient future for the industry.

Featured Posts

-

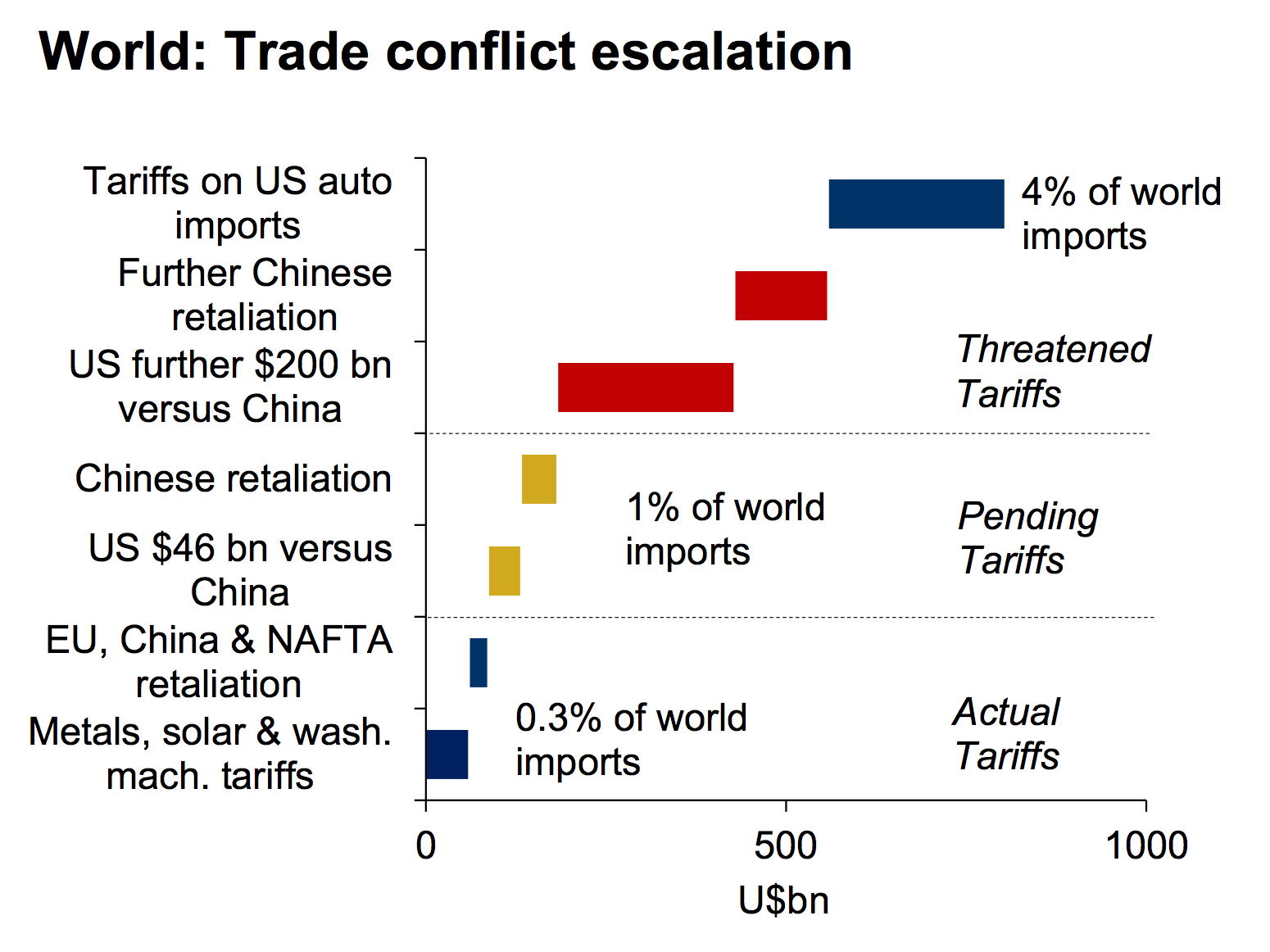

Trumps Trade War A Threat To Us Financial Leadership

Apr 22, 2025

Trumps Trade War A Threat To Us Financial Leadership

Apr 22, 2025 -

Obamacares Future Hangs In The Balance Trumps Supreme Court Argument And Rfk Jr S Political Prospects

Apr 22, 2025

Obamacares Future Hangs In The Balance Trumps Supreme Court Argument And Rfk Jr S Political Prospects

Apr 22, 2025 -

Bof As Take Why High Stock Market Valuations Shouldnt Worry Investors

Apr 22, 2025

Bof As Take Why High Stock Market Valuations Shouldnt Worry Investors

Apr 22, 2025 -

South Sudan Us Collaboration On Deportees Repatriation

Apr 22, 2025

South Sudan Us Collaboration On Deportees Repatriation

Apr 22, 2025 -

Toxic Chemical Fallout The Long Term Impact Of The Ohio Derailment

Apr 22, 2025

Toxic Chemical Fallout The Long Term Impact Of The Ohio Derailment

Apr 22, 2025