US Port Fees To Hit Auto Carrier With $70 Million

Table of Contents

The $70 Million Fee: A Breakdown of the Charges

The $70 million fee levied against the unnamed auto carrier (confidentiality agreements prevent public disclosure of the carrier's name) resulted from a confluence of factors, primarily related to significant delays and extended dwell times at major US ports. The charges encompass a range of penalties including late fees, demurrage, and extensive storage charges.

-

Specific Charges: The breakdown includes substantial per-day demurrage rates, accumulating rapidly due to prolonged container dwell time. High storage fees per container were also incurred as cargo remained at the port for extended periods. Terminal handling charges added further to the accumulating costs.

-

Ports Involved: While the exact ports are not publicly available, initial reports indicate significant delays occurred at multiple major West Coast ports, known for their recent congestion issues.

-

Fee Calculation: These fees are calculated based on several factors. Container dwell time, the length of time a container remains at the port, is a key determinant. Port congestion charges, often levied when delays are outside the control of the carrier, also contribute significantly. Finally, terminal handling charges, based on the processing and movement of containers, further inflate the total cost.

Impact on the Automotive Industry and Consumers

This incident has far-reaching consequences for the automotive industry and ultimately, consumers. The $70 million fee is a stark indicator of the increasing financial pressures impacting the sector.

-

Increased Vehicle Prices: The added costs will undoubtedly be passed on to consumers, leading to potential increases in vehicle prices. This adds to existing inflationary pressures and could dampen consumer demand.

-

Delivery Delays: Port congestion and associated fees frequently lead to significant delays in vehicle deliveries. This impacts both automakers and consumers, who face longer wait times for their vehicles.

-

Profit Margin Pressure: The increased shipping costs directly impact automakers' profit margins, squeezing an already competitive industry. This may lead to cost-cutting measures or reduced investment in other areas.

-

Vehicle Availability: The ripple effects of port congestion and high fees could also impact the availability of certain vehicle models, particularly those reliant on just-in-time manufacturing and delivery schedules.

Port Congestion: A Systemic Problem Exacerbating Costs

The $70 million fee isn't an isolated incident; it highlights a larger systemic problem: persistent port congestion in the US. This congestion significantly increases shipping costs and disrupts the automotive supply chain.

-

Contributing Factors: Several factors contribute to this ongoing issue, including labor shortages at ports, outdated infrastructure struggling to cope with increased import volumes, and inefficient processes.

-

Long-Term Implications: If unchecked, chronic port congestion will continue to increase shipping costs, potentially impacting the overall competitiveness of US-based automotive manufacturing and hindering economic growth.

-

Potential Solutions: Port authorities and government agencies are exploring various solutions, including infrastructure investments to improve capacity, technological advancements to optimize port operations, and improved coordination across the supply chain.

Strategies for Mitigating Future Port Fee Increases

Auto carriers and importers can employ several strategies to reduce future port fee expenses and increase supply chain resilience.

-

Improved Forecasting and Visibility: Enhanced supply chain visibility and accurate forecasting can minimize delays and improve planning, leading to reduced dwell times and associated fees.

-

Optimized Shipping Schedules and Routes: Strategic route planning, considering port capacity and potential congestion, can significantly reduce delays and costs.

-

Efficient Port Operations and Container Management: Streamlining processes, leveraging technology for real-time tracking and improved communication with port authorities can contribute to smoother operations and reduced fees.

-

Negotiation with Port Authorities: Proactive negotiation with port authorities for favorable rates and potential waivers can help mitigate some of the financial risks.

Conclusion

The staggering $70 million in US port fees levied on an auto carrier serves as a stark warning of the escalating costs and challenges facing the automotive supply chain. This incident highlights the significant financial burden imposed by port congestion, impacting automakers, and ultimately, consumers. The impact extends beyond the automotive industry, illustrating the need for comprehensive solutions to address systemic issues within US ports. Understanding and mitigating the risks associated with US port fees is crucial. Learn more about strategies for managing US port fees and improving supply chain resilience to avoid similar costly scenarios. Contact [your company/relevant resource] to learn more about optimizing your supply chain and navigating the complexities of US port fees.

Featured Posts

-

American Battleground Confronting The Worlds Richest Man

Apr 26, 2025

American Battleground Confronting The Worlds Richest Man

Apr 26, 2025 -

Switch 2 Preorder Success My Game Stop Experience

Apr 26, 2025

Switch 2 Preorder Success My Game Stop Experience

Apr 26, 2025 -

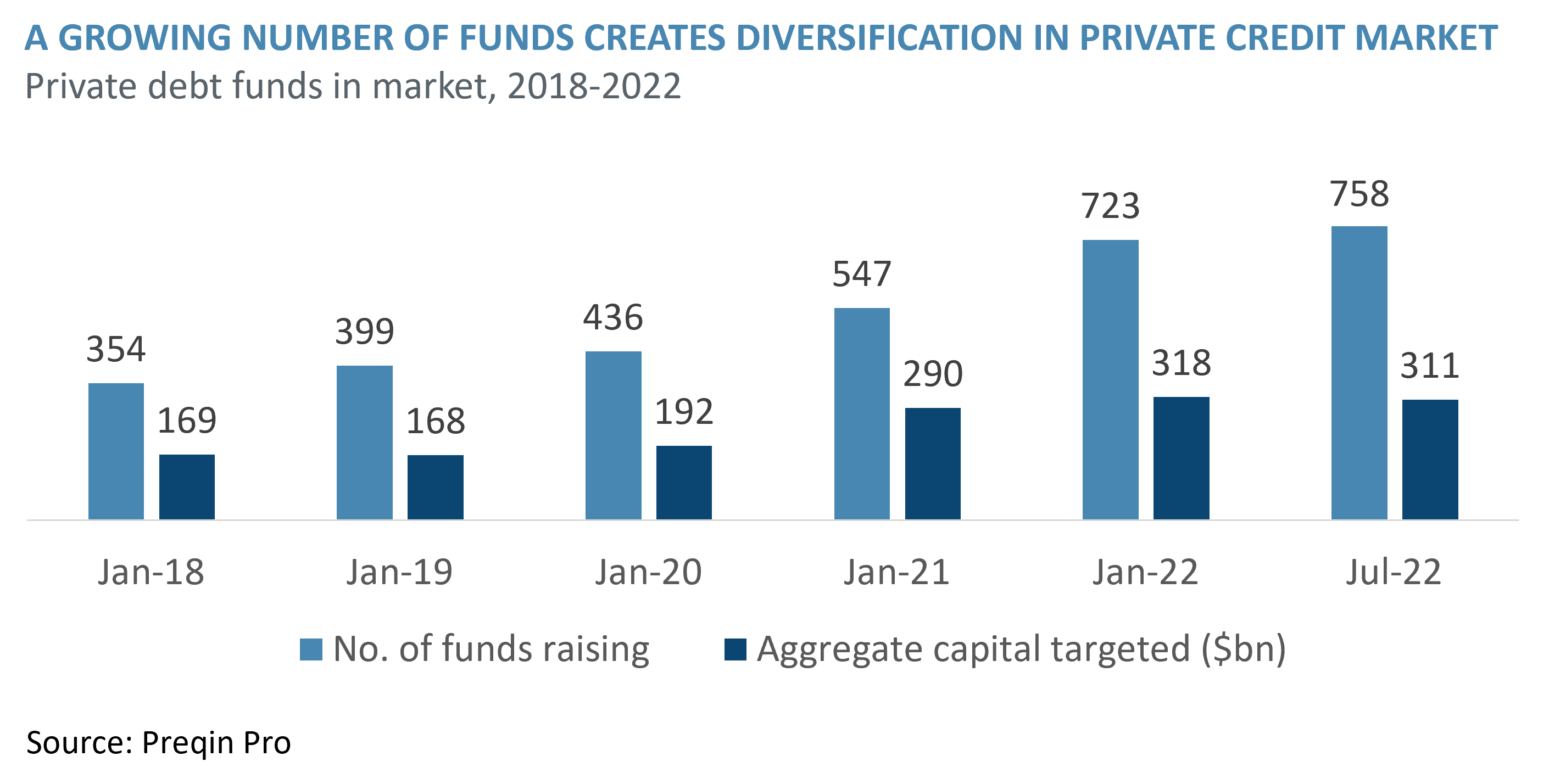

5 Essential Dos And Don Ts Succeeding In The Private Credit Market

Apr 26, 2025

5 Essential Dos And Don Ts Succeeding In The Private Credit Market

Apr 26, 2025 -

I Got My Switch 2 Preorder The Game Stop Line Experience

Apr 26, 2025

I Got My Switch 2 Preorder The Game Stop Line Experience

Apr 26, 2025 -

2700 Miles From Dc How Trumps First 100 Days Affected A Rural School

Apr 26, 2025

2700 Miles From Dc How Trumps First 100 Days Affected A Rural School

Apr 26, 2025